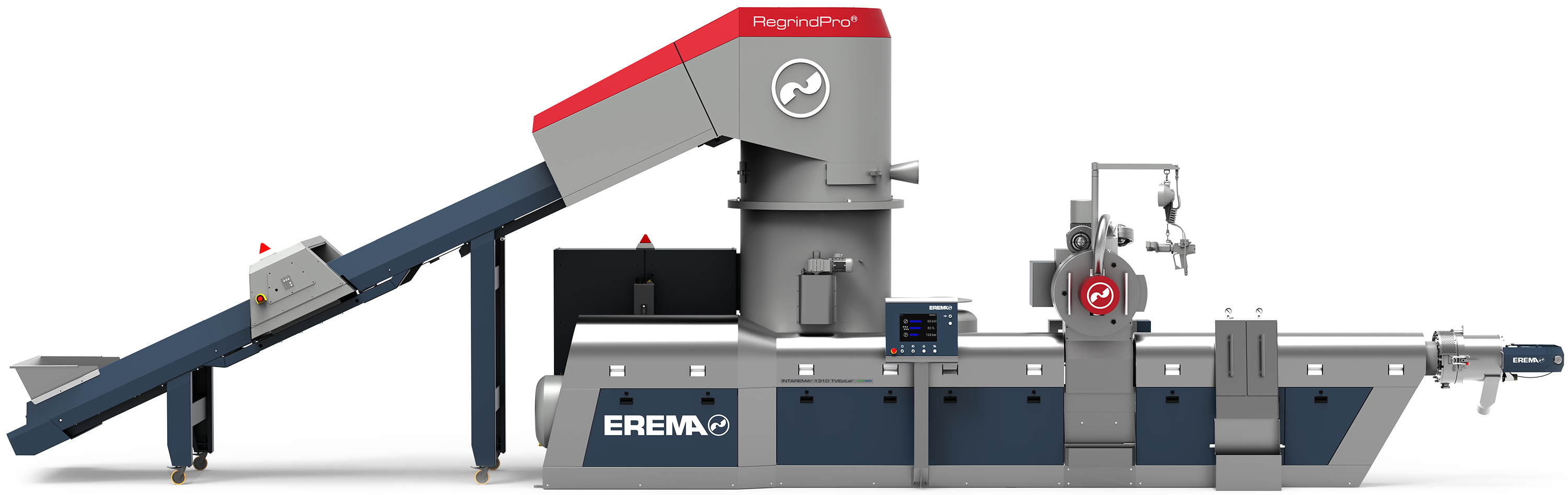

The INTAREMA® RegrindPro® goes a new way. The gentle way. This is how it converts thickwalled regrind into top recycled pellets. Perfectly filtered. Perfectly degassed. And in a quality that allows you to produce end products with top functional characteristics. For example in terms of surface quality or mechanical properties.

One of the key factors: Thanks to the preconditioning unit the extruder is fed warm instead of cold. The advantage over conventional systems: a short extruder screw is enough to melt the already dry and thoroughly warmed regrind particles. The shear stress is extremely low as a result while the melt quality is high – from the very beginning.

Uncompromisingly gentle regrind processing for top recycled pellet quality

The end products produced are convincing with top functional characteristics in terms of mechanical properties, surface quality, dyeability, smell, etc. and with a particularly high recycled pellet content

Remarkably high-performance filtration: the EREMA Laserfilter removes undesired impurities particularly effectively

Considerably higher filtration efficiency compared to conventional single and twin screw systems

Wide variety of regrind types under perfect control – without screw exchange, with consistently high capacities

Very broad input bulk density range from 30 to 800 g/l – therefore ideally suitable for both regrind and other types of material such as film, sheet and nonwoven applications

Save set-up costs, increase productivity: with the material all-rounder you remain as flexible as possible!

The innovative system unites all the benefits of the INTAREMA® plant generation such as the top technologies Counter Current, Smart Start and ecoSAVE®, which set the standard in production efficiency in plastics recycling.