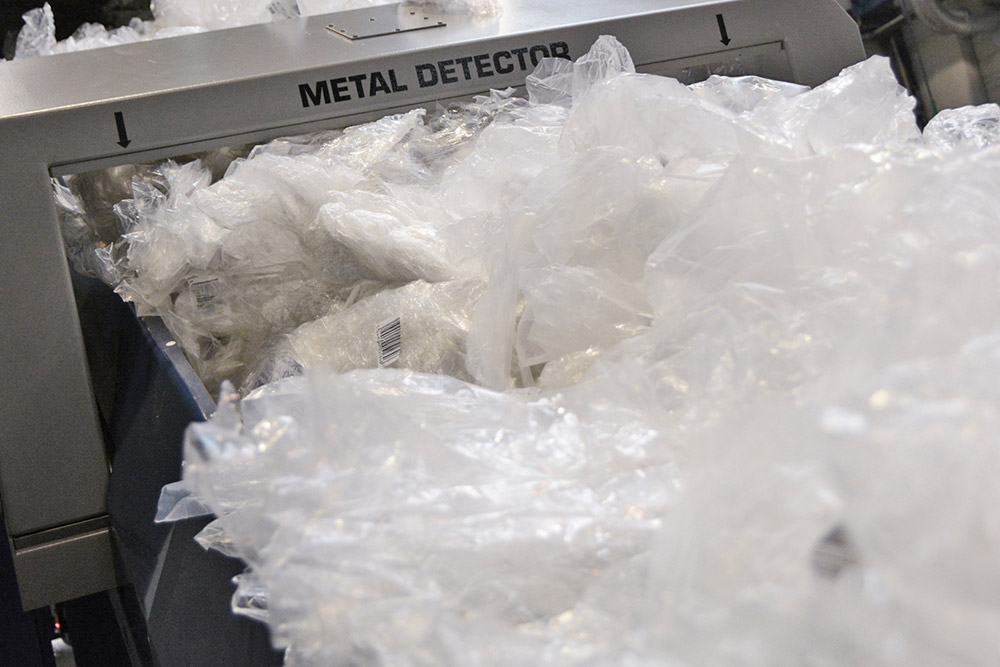

PE, PP, ABS or PS – the new RegrindPro® processes these and other regrind types into top recycled pellets. Typical regrind sources are: packaging, automotive applications, waste electrical and electronic equipment (WEEE), household, building/construction, etc.

Thanks to the top recycled pellet quality the end products produced are convincing with top functional characteristics in terms of mechanical properties, surface quality, dyeability, smell, etc.

One single machine which turns a wide variety of regrind types into high-quality recycled pellets? RegrindPro® technology makes it possible: thanks to the thorough warming through of the input material in the preconditioning unit and a particularly gentle universal screw it ingeniously processes an extremely wide range of polymers with different melting points and energy contents.

As a result you change very quickly between PE, PP, ABS, PS and other regrind types – and without exchanging screws! Plus: there are no compromises in terms of throughout and quality. This is flexibility that lowers your set-up costs and increases your productivity!

Your flexibility bonus: thanks to the extremely broad input bulk density range of 30 to 800 g/l the system is ideally suitable for both regrind and other types of material such as film, sheet and nonwoven applications.

The high-performance machine is thus the absolute material all-rounder. Highly flexible, strong performance and energy-saving. And extremely easy to operate.