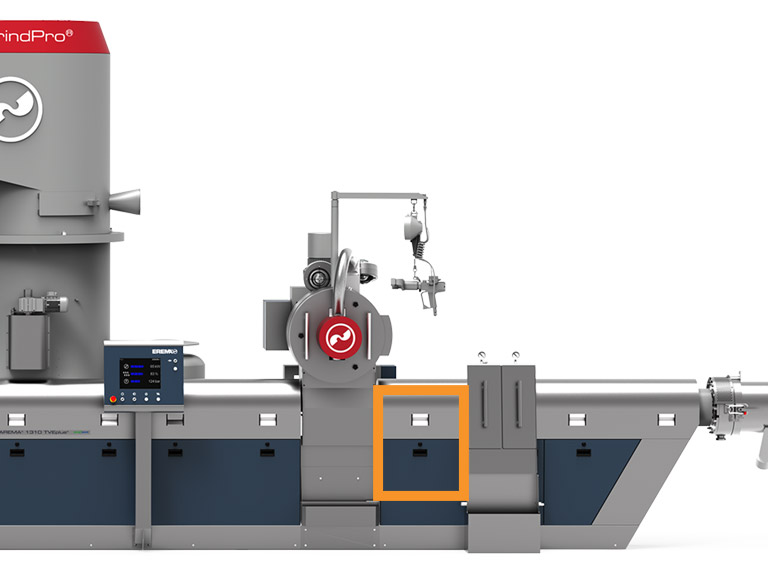

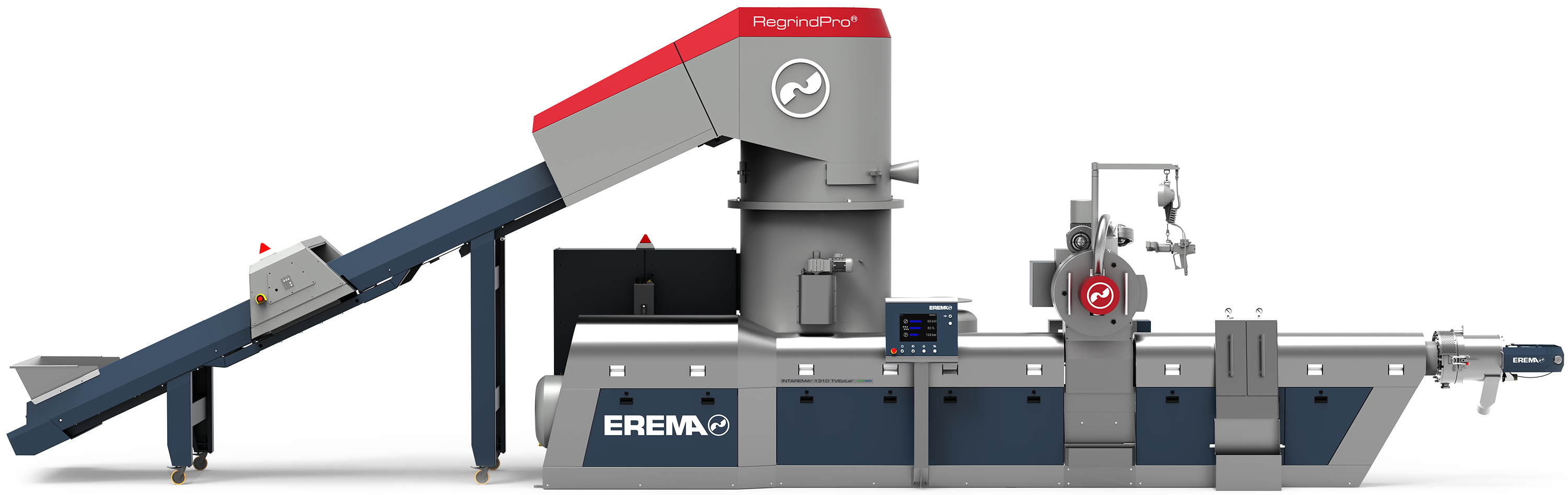

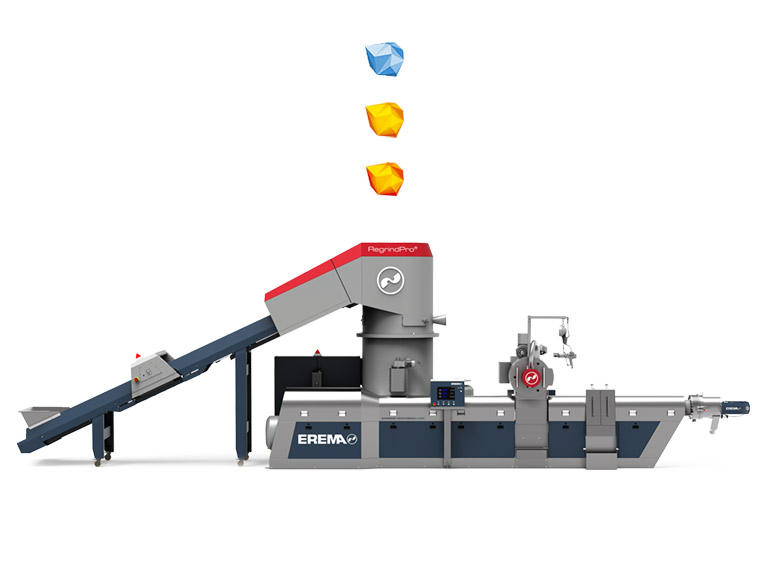

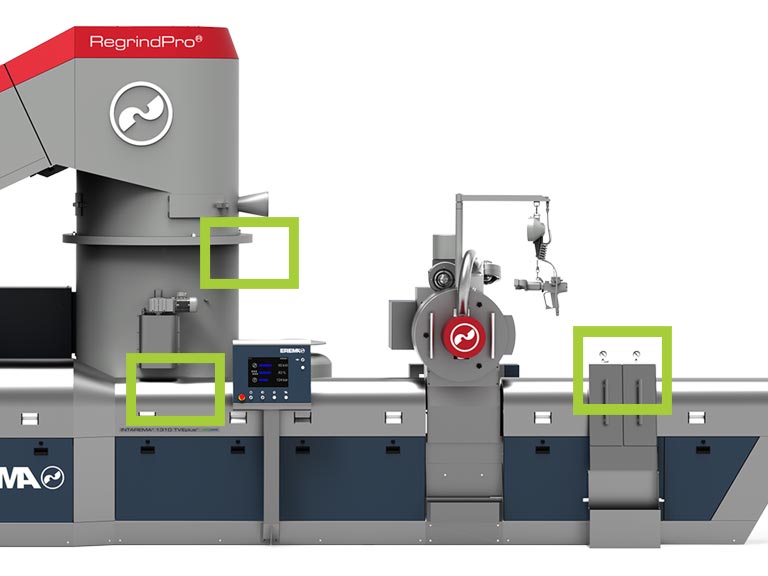

Are you looking for the ultimate way of producing top recycled pellets from thick-walled regrind? For end products with best performance properties and a particularly high recyclate content? The new INTAREMA® RegrindPro® offers the ideal solution: extremely gentle processing in combination with high-performance filtration. A true material all-rounder so you remain as flexible as possible.

Go the gentle way – The six steps to success

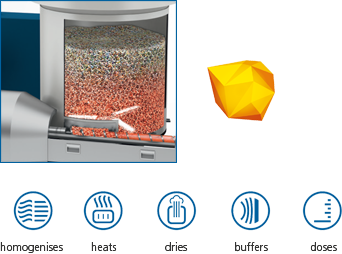

The gentle way begins in the preconditioning unit. It gives the thick-walled regrind particles what they need to be warmed through homogeneously: a longer residence time. This is made possible by a slower turning of the new rotor disc with a higher filling level at the same time. Consequently even high moisture disappears and the regrind is perfectly prepared for the extruder.

Additional bonus: fillers such as CaCO3 are distributed homogeneously thanks to the longer residence time and high filling level.

RegrindPro®. Go the gentle way.

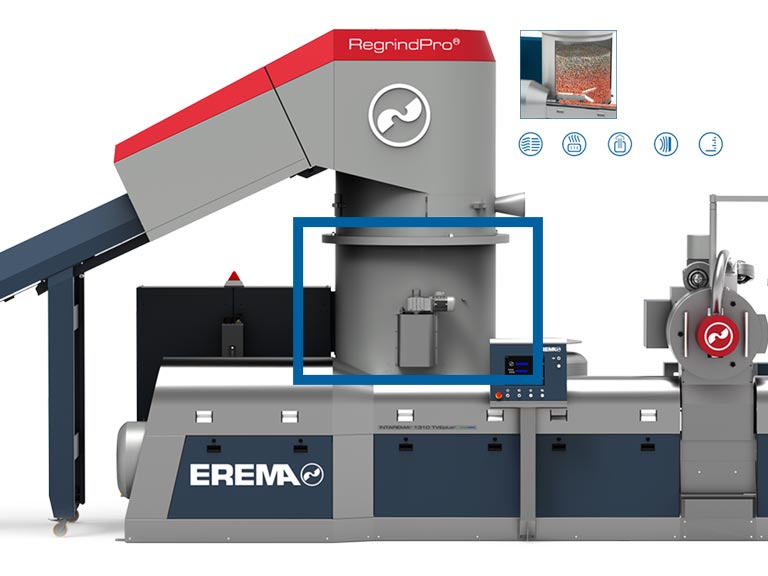

Thanks to the preconditioning unit the extruder is fed warm instead of cold. The advantage over conventional systems: a short extruder screw is enough to melt the already dry and thoroughly warmed regrind particles. The shear stress is extremely low as a result while the melt quality is high.

RegrindPro®. Go the gentle way.

Clean melt, pure performance: efficient filtering is one of the key strengths of the new RegrindPro®. Thanks to the gentle preparation in advance the EREMA high-performance Laserfilter has an easy time. Dirt particles and impurities such as silicones are hardly reduced in size before and are therefore large enough for them to be easily removed from the melt.

The early removal of undesired materials means they can no longer outgas and no unpleasant smells develop – a decisive quality bonus for the melt.

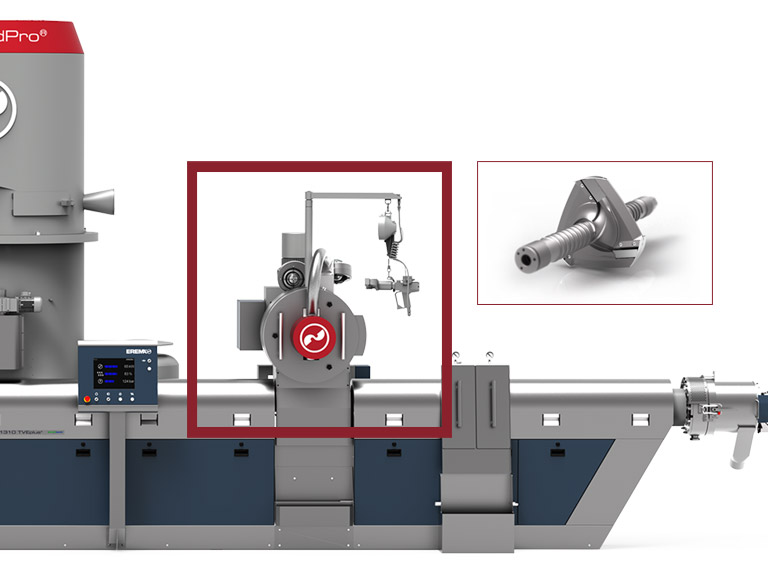

Optimised high performance: through the redesign of the Laserfilter scraper geometry, rubber-like, non-melting contaminants such as silicones and linked polymers are lifted particularly quickly and continuously from the screen – and thus filtered even more effectively.

RegrindPro®. Go the gentle way.

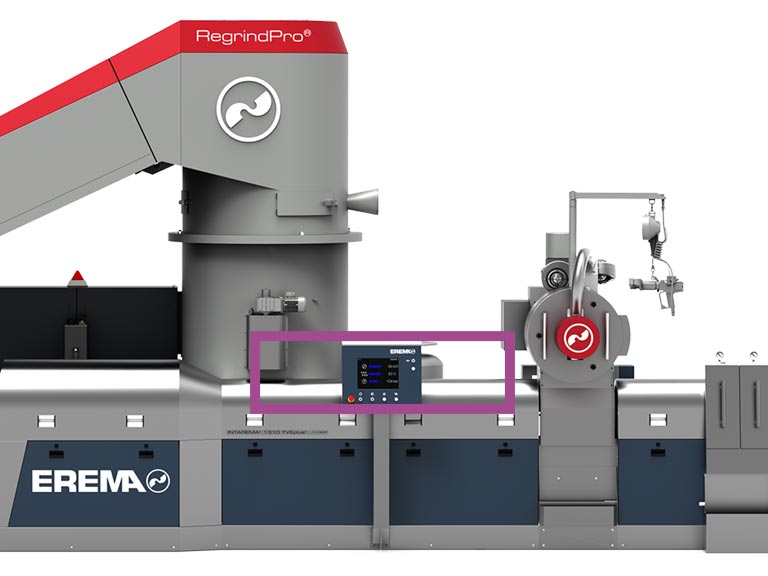

The final homogenisation of the melt downstream of filtration and upstream of degassing enhances

the subsequent degassing performance and improves the characteristics of the melt.

RegrindPro®. Go the gentle way.

The new RegrindPro® features convincing, high-performance degassing. This takes place very effectively in three stages: initial degassing already occurs in the preconditioning unit. Step two is reverse extruder degassing – made possible through optimised screw design. The final double venting degassing at the extruder is particularly effective and removes gas inclusions which are still present from the melt.

The melt is now clean, homogenised and perfectly degassed.

And thus: ready for pelletising. RegrindPro®. Go the gentle way.